Tech

Toyota halts all Japan assembly plants due to glitch

Japanese motor industry giant Toyota has suspended operations at all of its assembly plants in its home country due to a glitch in its production system.

The move has brought domestic production at the world’s biggest-selling car maker to a standstill.

The malfunction has meant the firm has not been able to order components.

A spokesperson told the BBC that the firm is trying to find the cause of the problem but does not currently believe it is due to a cyber attack.

On Tuesday morning, Toyota suspended operations at 12 of its 14 assembly plants in Japan.

Later in the day a spokesperson said production at all 14 facilities would be suspended.

The company has not yet said when it plans to restart the operations or how much production is expected to be lost due to the stoppage.

In total, the 14 plants are estimated to account for around a third of Toyota’s global production.

The suspension comes as Toyota’s production in Japan had been recovering after a series of issues.

Its operations were hit last year after one of its suppliers was affected by a cyber attack.

The one-day disruption caused an output loss of around 13,000 cars.

Also last year, Toyota suspended operations at some of its production lines in Japan due to the coronavirus lockdown in China’s economic hub Shanghai.

“Due to the impact of the semiconductor shortage, we announced our revised production plan for May,” Toyota said at the time.

Toyota is a pioneer of the so-called “just-in-time” production system, which keeps costs down but can be vulnerable to problems if deliveries of components are disrupted.

Politics21 hours ago

Politics21 hours agoWe Will Bury PDP, Ibori’s Daughter Blows Hot

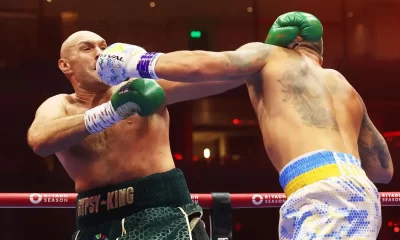

Sports21 hours ago

Sports21 hours agoOleksandr Usyk defeats Tyson Fury to tetain heavyweight title

News21 hours ago

News21 hours agoNigerian Emergency Agency NEMA Puts All Offices On Alert Over Fatal Stampedes

Top Stories21 hours ago

Top Stories21 hours agoEmefiele: EFCC secures final forfeiture of 1.925 hectares of landed property linked to former CBN Governor

Sports21 hours ago

Sports21 hours agoCAF Made Me Believe I Won – Achraf Hakimi

- News9 hours ago

NIGERIAN BREWERIES PARTNERS OZA CARNIVAL